Area A

The Royal Arsenal Woolwich historic buildings report volume 2 - 1994 covers the following buildings: Brass Foundry, Royal Carriage Factory, Grand Store, Building 41/41A, Building 17, and Building 25. Each building has its own history, design, and construction. The report includes illustrations, photos, and plans of each building.

Timestamps in the description. This video is best viewed in 1080p in the YouTube quality video setting cog.

To slow down or speed up this video there is a function for ‘playback speed’ on the YouTube settings and can be paused at any time.

00:00:00 Intro slideshow example photos

00:00:54 Historic Buildings report volume 2

00:01:01 Brass foundry summary

00:01:11 Brass foundry introduction

00:01:18 Brass foundry finer detail report

00:10:57 List of illustrations Brass Foundry

00:11:18 Brass foundry photos/plans/interior

00:13:32 Brass foundry then and now

00:15:48 Brass foundry prints with descriptions

00:23:50 Building 10 RCF Royal Carriage Factory summary

00:27:01 List of illustrations RCF

00:27:01 Royal Carriage Factory photos/plans/interior

00:28:21 Royal Carriage Factory photos

00:29:45 The Grand Store Building summary 36, 37, 46 and 49

00:30:18 The Grand Store finer detail report

00:37:14 List of illustrations the Grand Store

00:37:33 Grand Store plans/interior

00:39:07 Grand Store photos

00:41:24 Building 41/41A (New Laboratory Square) summary

00:41:55 Building 41/41A finer detail report

00:45:04 List of illustrations Building 41/41A

00:45:16 Building 41/41A Plans

00:45:16 Building 41/41A photos

00:48:35 Building 17 paper cartridge factory summary

00:48:57 Building 17 finer detail report

00:55:08 List of illustrations Building 17

00:55:18 Building 17 plans

00:55:38 Building 17 photos/plans

00:56:52 Building 25 the Armstrong Gun Factory summary

00:57:15 Building 25 finer details

01:00:56 List of illustrations Armstrong Gun Factory

01:01:40 Armstrong Gun Factory plans

01:03:00 Armstrong Gun Factory photos

To slow down or speed up this video there is a function for ‘playback speed’ on the YouTube settings and can be paused at any time.

00:00:00 Intro slideshow example photos

00:00:54 Historic Buildings report volume 2

00:01:01 Brass foundry summary

00:01:11 Brass foundry introduction

00:01:18 Brass foundry finer detail report

00:10:57 List of illustrations Brass Foundry

00:11:18 Brass foundry photos/plans/interior

00:13:32 Brass foundry then and now

00:15:48 Brass foundry prints with descriptions

00:23:50 Building 10 RCF Royal Carriage Factory summary

00:27:01 List of illustrations RCF

00:27:01 Royal Carriage Factory photos/plans/interior

00:28:21 Royal Carriage Factory photos

00:29:45 The Grand Store Building summary 36, 37, 46 and 49

00:30:18 The Grand Store finer detail report

00:37:14 List of illustrations the Grand Store

00:37:33 Grand Store plans/interior

00:39:07 Grand Store photos

00:41:24 Building 41/41A (New Laboratory Square) summary

00:41:55 Building 41/41A finer detail report

00:45:04 List of illustrations Building 41/41A

00:45:16 Building 41/41A Plans

00:45:16 Building 41/41A photos

00:48:35 Building 17 paper cartridge factory summary

00:48:57 Building 17 finer detail report

00:55:08 List of illustrations Building 17

00:55:18 Building 17 plans

00:55:38 Building 17 photos/plans

00:56:52 Building 25 the Armstrong Gun Factory summary

00:57:15 Building 25 finer details

01:00:56 List of illustrations Armstrong Gun Factory

01:01:40 Armstrong Gun Factory plans

01:03:00 Armstrong Gun Factory photos

A HD video with WW1 map zoomed in, building departments, reference numbers are at the end between 1914 - 1967

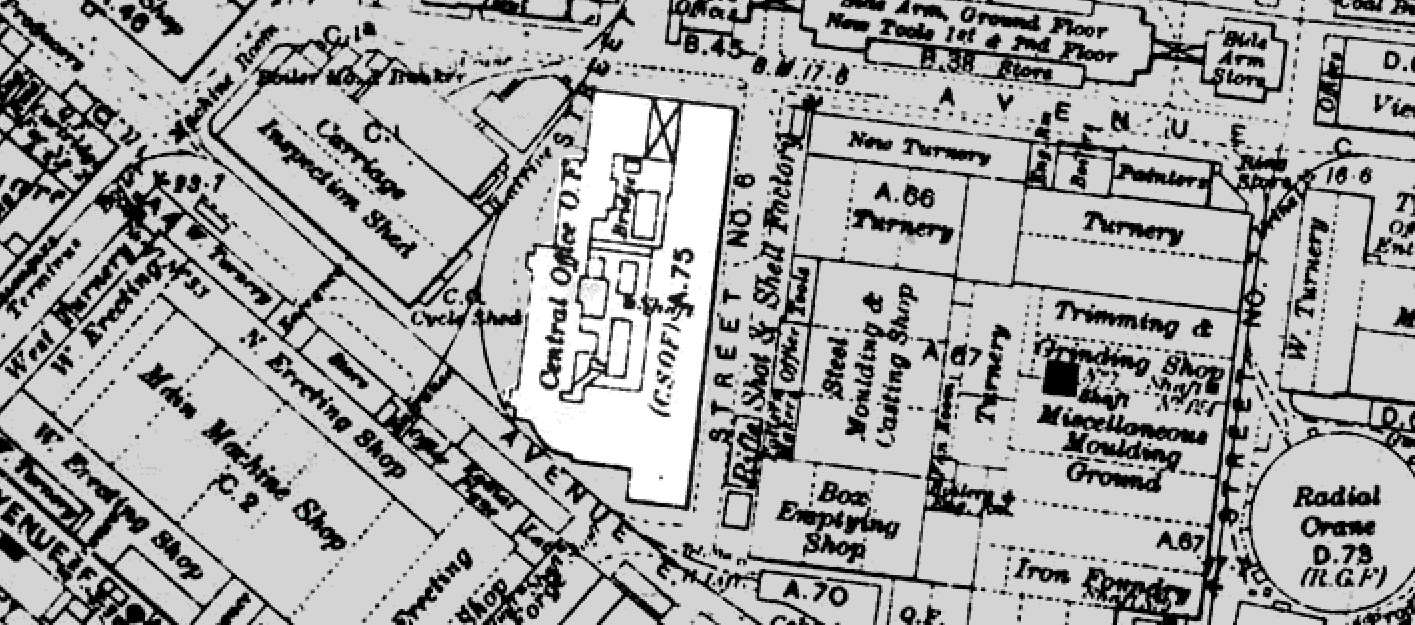

BUILDING A75 / BUILDING 22 - Central Offices or MyHQ

Also known as Building 22 (Central Offices or MyHQ) An office building for central staff was built south of Verbruggen’s House in 1888–90, but the separate departments continued in their own offices. In 1902 an Ordnance Factories committee was set up to enquire into cost accounting, a matter that concerned H. F. Donaldson as Deputy DirectorGeneral. One of its recommendations in 1904 was that the offices of the Arsenal’s departments should be brought together. Donaldson evidently anticipated this conclusion, as designs for central offices were being made in 1903. Government approval was obtained and a massive office complex went up in 1905–11 in front of the Shot and Shell Foundry, displacing the Carriage Department offices. The partially completed building first came into use in 1908 to serve as the administrative centre of the entire Arsenal, then about three miles long. An outside architect, James Osborne Smith, perhaps best known for the London Library in St James’s Square, had been brought in to design what is, progressively for its date, a wholly steel-framed building. Earlier in his career Osborne Smith had been engaged in the Office of Works on the fitting up of the Natural History Museum and he was a close friend of Sir Henry Tanner, a structural innovator. Col. Arthur Henry Bagnold, RE, was responsible for supervising the works at the Arsenal, and steel was supplied by Dorman Long & Co. of Middlesbrough. It may be that the building was structurally up to date in another respect – Hennebiquesystem reinforced-concrete foundation piles were supplied to the War Office in Woolwich in 1905. They were probably for this project; poor ground conditions would have been a concern. The offices are a loosely rectangular aggregation of blocks around an internal service courtyard, rising three storeys above a basement, with some attics. The internal frame carries elevations of stock brick, dressed with red brick and stone, in a heavy neo-Georgian style with Baroque touches. The main southern part of the entrance front to the west is symmetrical with projecting ashlar to its centre and ends. There is rustication around the main central entrance arch which bears the date 1908. Above, a pediment carries the Royal Cypher of King Edward VII. Another stone entrance bay to the north has Royal Arms in its pediment. The plainer east side has a nearly flat elevation of thirty-four bays. In the courtyard cream-glazed brick elevations were linked by a covered bridge at first-floor level in latticed steelwork, an early addition that was removed around 2005. Inside, along with the steel frame, there were concrete floors above the lower storeys and internal walls of concrete poured in situ. The main entrance hall had a coffered ceiling with marbled columns and pilasters. It led to the principal staircase which rose round a lift well with ornamental iron balustrading. Other staircases were lined with glazed brick. The best offices, for the several superintendents, were on the first floor in the main part of the west range. On the top floor there was a drawing office, the superintendents’ mess, and, from 1917, a telephone exchange. The basement was reinforced for use as an air-raid shelter in the Second World War. The building did suffer a direct hit and its southern parts had to be reconstructed. Attics were extended to the south in 1967–8 when the complex became a headquarters for defence inspection (quality assurance) directorates. In 2004–7 Berkeley Homes replaced those additions and added a further additional set-back storey in a conversion to provide 388 flats, with a shop in the northern entrance archway. For this Broadway Malyan were architects, and the building, thoroughly refenestrated, was renamed ‘MyHQ’

BUILDING A79 - Medical department Surgery, Mortuary & Dispensary

Area B

Area C

Area D

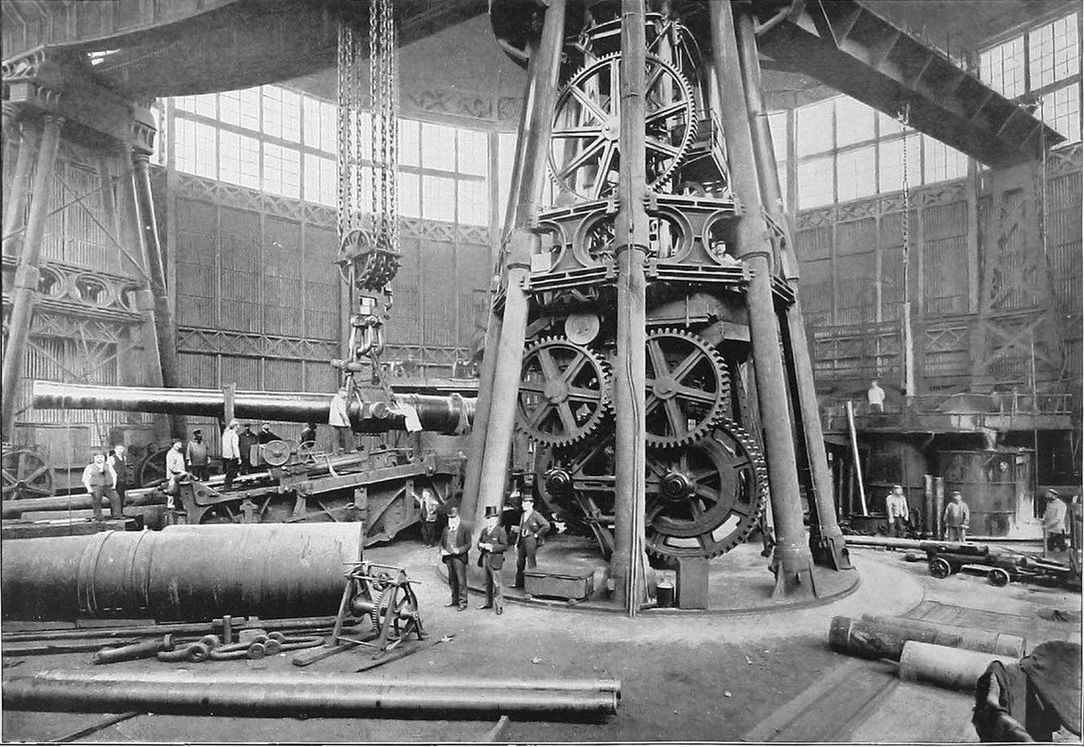

D73 The radial steam crane roundhouse also known as the rink.

This was placed west of the south forge in 1876 by Campbell’s successor, Gen. C. W. Younghusband, with Scratchley still in charge of works. It was for shrinking and tempering – the crane, which had a capacity of 250 tons, lifted hot gun barrels of up to twenty-five tons into and out of underground oil pits. In 1891–2 Col. Sale and John Lysaght Ltd of Bristol, contractors, roofed it on an enclosing 72ft(22m)-tall free-standing steel frame with wrought-iron cross bracing; this was replaced in 1939. Latterly called the Rink or Roundhouse, it was demolished in 1966.

1880 - THE MOST POWERFUL CRANE IN THE WORLD!

The colossal crane at Woolwich, which has been upwards of four years in process of erection.

Construction started in 1876, but it was not completed until 1880. This was steam powered.

The crane was exposed to the elements until a roundhouse was built for it after 1892.

1891 photos show building the cover over Radial Crane known as the Rink, Roundhouse, building number D73.

The building was built around a large machine called the Radial Crane. The crane had three arms and as it revolved it picked-up white hot gun barrels and then plunged them into pits full of oil. This relieved the stress caused in them by the hot processes they'd been through and also gave them a degree of resistance to rusting. The building was something of a centrepiece in the Arsenal and its loss in 1966 indicated the end of some hundreds of years of superlative manufacturing.

Worcester Journal, 4 December 1880:

THE MOST POWERFUL CRANE IN THE WORLD. The colossal crane at Woolwich, which has been upwards of four years in process of erection, assumed a definite shape on Tuesday, in the operation of fixing the great girder. The immensity of the work is illustrated by the weight of the iron employed in its construction, which, in the aggregate, exceeds 1,800 tons, while the brass bearings alone amount to more than three tons. When completed the crane will be capable of lifting three or four 100-ton guns at once; but the purpose for which it has been provided is not to do work which other appliances could accomplish in detail, but rather to meet the probable necessity for dealing with specimens of ordnance so enormous as to defy all the means at present available for mounting them in their carriages. The motive power will be steam. Although calculated raise to 1,200 tons in case of need, the apparatus will also be fixed for raising small weights at accelerated speed, and it is anticipated that, even in the ordinary daily work of the Royal gun factories, to which department it belongs, it will prove a valuable auxiliary.

Manchester Courier and Lancashire General Advertiser - Friday 22 September 1876

THE 200-TON CRANE.

Monster guns require appliances to assume a corresponding magnitude and power. Were this condition not complied with such guns could not be made; or, if made, could not be managed. One essential contrivance is of the crane, and it is desirable that this should not only be equal to lifting of certain weight, but should be able to operate over as large an area as possible. For the purposes of the Royal Gun Factories this latter feature is particularly important, and the attention of the public has been directed on more than one occasion in these columns to the fact that a new description of crane is in course of construction at Woolwich Arsenal, the design of which is directed to the lifting of great weights over an enlarged area.

The general plan of the crane originated with Mr. Fraser, and its details have been very felicitously worked out. As every invention requires a name, this has been designated "sweep crane," though perhaps a better title may yet be suggested. The progress made with this new structure shows itself in the shape of several heavy castings, and the foundry at the Arsenal scarcely affords space for the requisite operations, coupled with the other work which has to go on. Including all the various parts the machine, the new crane is estimated to require about 800 tons of iron, and some two or three tons of bronze. All the bearings will be bushed with the same material.

The locality of the colossal crane thus about to be constructed is a piece of ground contiguous to the building which contains another trophy of modern mechanism, the 40-ton steam hammer. On the open space thus appropriated the workmen have commenced digging out the foundations and laying the concrete. Although the work is thus taken in hand, it will be between one or two years before is completed, and there can be little doubt that by the time the crane is actually in operation the need for such machine will be even more apparent than it is now, proceeding to describe the forthcoming structure, must, for the sake of perspicuity, speak of it as already existing, though it will be understood that the design as yet can only be realised the shape of plans and drawings. Speaking, therefore, from the plans, and not from the positive reality, we proceed to describe the general structure of the crane as consisting of two groups of columns, about 50 feet high, including the capitals, supporting a compound girder, 75 feet in length. This immense girder, which stretches across like a flat bridge from one group of columns to the other, there travels to and fro what is called the chain carriage.

When the crane is in operation the weight to be lifted and moved will appear suspended from this carriage. The great cross girder which bears the carriage is itself the moving radius of a circle, one extremity of the girder rotating on the summit of one group of columns, while the other extremity, supported by the other group of columns travelling on wheels, sweeps round through the whole circumference of circle which has a diameter of 134 feet. The space over which the chain carriage will be able to operate, after allowing for the obtrusion of the columns, is that of annulus, beginning 15 feet from the centre of the circle, and having a breadth of 47 feet The area will therefore be about 11,370 square feet, or nearly a quarter of an acre.

The cast-iron columns which occupy the centre of the area are eight in number, fixed at equal distances on annular girder 30 feet in diameter, firmly embedded in concrete. These columns are 43 feet in vertical height and slope slightly inwards, so as to be fixed at their summit to an annular girder or entablature 16 feet in diameter. The columns are 20 inches in diameter, and each column is made in two lengths, the joint being about half way up, where the entire eight are braced together by a ring of cast-iron of ornamental design. The space enclosed by these columns, representing the frustrum of a large hollow cone, will be occupied by the engines which are to work the crane, together with a quantity of gearing.

The engines and gearing thus enclosed will derive their support not from beneath but from above, though they will be steadied a central pivot at base. The support from above is given by means of four cast-iron columns, slung from a revolving capital designated the "roller cap." As the radius girder sweeps round the circular area so the capital of the central group of columns revolves with it, carrying the engines and gear supported on a stage at the lower end of the four interior columns. The revolving capital travels on live rollers of cast iron 16 inches in diameter, interposed between the capital and the annular girder entablature which holds the summits of the eight columns.

Summarising the vertical dimensions of this part of the crane, we have first of all the eight columns rising to altitude of 43 feet, supporting an entablature four feet in depth, being the upper annular girder. On this are the live rollers, supporting cast-iron "cap," or capital, which adds 3ft. 6in. to the vertical height. On this again comes a centreing piece, 2 ft. deep, hollowed in its centre so as to cover what may be termed a knob of metal, 18in. high, in shape resembling half an egg standing on its base, and rising up from the roller cap. This arrangement constitutes what is termed "knuckle bearing." The extremity of the great horizontal girder being attached to the strong casting centreing piece which we have just described, and the same knuckle bearing arrangement existing at the other end, a proper amount of play is allowed, supposing there should be any deflection when lifting heavy weights. Proceeding to speak more particularly of the radius girder which connects the summits of the centre and outer groups columns, we must specify it as composed of two horizontal wrought-iron girders of the bore [box?] type, about 75 feet in length, with a depth increasing towards the centre, where it is 8 feet 6 inches, The chain carriage, supported on eight wheels, runs on rails attached to the upper flanges of the two girders, and is traversed from end to end by means of chains and gearing worked by the engines previously named. This carriage bears the lifting blocks, which are of large size, having cast-iron sheaves about four feet in diameter The outer extremity of the girder—or compound girder— on which this carriage runs, is supported by six cast-iron columns of somewhat similar design to the eight which are at the inner end. The six outer columns spring from an iron carriage running on eight wheels about five feet diameter. These wheels are arranged in four following pairs, and travel on rails of the regular railway gauge, namely 4ft 8½ in. The circle traversed by this carriage has a diameter of 136 feet measuring to the centre of the rails. The rails are ribs raised on plates. The wheels of the carriage are made to rotate by gearing set in motion from the engines by two vertical shafts and one cross shaft. That is to say, the shafting extends up the central group of columns, along the top girder, and down the outer group. The revolution of the wheels on the railway gives motion to the whole structure, the great top girder sweeping round over the entire space. The actual height to the top of the horizontal girder is feet inches. The extreme height, going to summit of the chain carriage, is about 70 feet.

The engines in the central group of columns will consist of two steam cylinders, 16 inches in diameter, and with a 16-inch stroke. The steam will be supplied from the forge boilers, which are adjacent. When a heavy weight has to be lifted these engines will work the spur gearing acting on two chain barrels each six feet in diameter.

There will be lighter gear for inferior loads to 20 tons, for which there will be independent chains working on two smaller barrels. The links of the great lifting chain will be composed of iron 2¼ inches in diameter. The crane is estimated to lift 200 tons; but the breaking strain of the girders will be six times that. The full lift of 200 tons will be worked at the ascending rate of half a yard per minute. The speed of the 100-ton lift is a yard per minute, and that of the 50-ton lift two yards per minute. The light lift of 20 tons will be worked at the rate of 14½ feet per minute. It will thus be seen that the action of this new description of crane requires a circular railway more than 400 feet in circumference, being the same gauge as that which characterises railways in general. The motive power will be under the control of one man, standing on the stage inside the central group of columns. By simply laying his hand on one or the other of set of levers this man will be able to direct all the movements of the great machine, lifting, if necessary, a couple of 81-ton guns at one time, with the addition of a 38-ton gun to make up a full load. This enormous weight will not only be lifted, but moved about with perfect facility over the space of nearly a quarter of an acre.

The crane was scrapped in 1937 and a new all-electric version installed

More info here on this video presentation (Start time copy 19:17) https://youtu.be/GW2aToc3xaU?t=1182

The colossal crane at Woolwich, which has been upwards of four years in process of erection.

Construction started in 1876, but it was not completed until 1880. This was steam powered.

The crane was exposed to the elements until a roundhouse was built for it after 1892.

1891 photos show building the cover over Radial Crane known as the Rink, Roundhouse, building number D73.

The building was built around a large machine called the Radial Crane. The crane had three arms and as it revolved it picked-up white hot gun barrels and then plunged them into pits full of oil. This relieved the stress caused in them by the hot processes they'd been through and also gave them a degree of resistance to rusting. The building was something of a centrepiece in the Arsenal and its loss in 1966 indicated the end of some hundreds of years of superlative manufacturing.

Worcester Journal, 4 December 1880:

THE MOST POWERFUL CRANE IN THE WORLD. The colossal crane at Woolwich, which has been upwards of four years in process of erection, assumed a definite shape on Tuesday, in the operation of fixing the great girder. The immensity of the work is illustrated by the weight of the iron employed in its construction, which, in the aggregate, exceeds 1,800 tons, while the brass bearings alone amount to more than three tons. When completed the crane will be capable of lifting three or four 100-ton guns at once; but the purpose for which it has been provided is not to do work which other appliances could accomplish in detail, but rather to meet the probable necessity for dealing with specimens of ordnance so enormous as to defy all the means at present available for mounting them in their carriages. The motive power will be steam. Although calculated raise to 1,200 tons in case of need, the apparatus will also be fixed for raising small weights at accelerated speed, and it is anticipated that, even in the ordinary daily work of the Royal gun factories, to which department it belongs, it will prove a valuable auxiliary.

Manchester Courier and Lancashire General Advertiser - Friday 22 September 1876

THE 200-TON CRANE.

Monster guns require appliances to assume a corresponding magnitude and power. Were this condition not complied with such guns could not be made; or, if made, could not be managed. One essential contrivance is of the crane, and it is desirable that this should not only be equal to lifting of certain weight, but should be able to operate over as large an area as possible. For the purposes of the Royal Gun Factories this latter feature is particularly important, and the attention of the public has been directed on more than one occasion in these columns to the fact that a new description of crane is in course of construction at Woolwich Arsenal, the design of which is directed to the lifting of great weights over an enlarged area.

The general plan of the crane originated with Mr. Fraser, and its details have been very felicitously worked out. As every invention requires a name, this has been designated "sweep crane," though perhaps a better title may yet be suggested. The progress made with this new structure shows itself in the shape of several heavy castings, and the foundry at the Arsenal scarcely affords space for the requisite operations, coupled with the other work which has to go on. Including all the various parts the machine, the new crane is estimated to require about 800 tons of iron, and some two or three tons of bronze. All the bearings will be bushed with the same material.

The locality of the colossal crane thus about to be constructed is a piece of ground contiguous to the building which contains another trophy of modern mechanism, the 40-ton steam hammer. On the open space thus appropriated the workmen have commenced digging out the foundations and laying the concrete. Although the work is thus taken in hand, it will be between one or two years before is completed, and there can be little doubt that by the time the crane is actually in operation the need for such machine will be even more apparent than it is now, proceeding to describe the forthcoming structure, must, for the sake of perspicuity, speak of it as already existing, though it will be understood that the design as yet can only be realised the shape of plans and drawings. Speaking, therefore, from the plans, and not from the positive reality, we proceed to describe the general structure of the crane as consisting of two groups of columns, about 50 feet high, including the capitals, supporting a compound girder, 75 feet in length. This immense girder, which stretches across like a flat bridge from one group of columns to the other, there travels to and fro what is called the chain carriage.

When the crane is in operation the weight to be lifted and moved will appear suspended from this carriage. The great cross girder which bears the carriage is itself the moving radius of a circle, one extremity of the girder rotating on the summit of one group of columns, while the other extremity, supported by the other group of columns travelling on wheels, sweeps round through the whole circumference of circle which has a diameter of 134 feet. The space over which the chain carriage will be able to operate, after allowing for the obtrusion of the columns, is that of annulus, beginning 15 feet from the centre of the circle, and having a breadth of 47 feet The area will therefore be about 11,370 square feet, or nearly a quarter of an acre.

The cast-iron columns which occupy the centre of the area are eight in number, fixed at equal distances on annular girder 30 feet in diameter, firmly embedded in concrete. These columns are 43 feet in vertical height and slope slightly inwards, so as to be fixed at their summit to an annular girder or entablature 16 feet in diameter. The columns are 20 inches in diameter, and each column is made in two lengths, the joint being about half way up, where the entire eight are braced together by a ring of cast-iron of ornamental design. The space enclosed by these columns, representing the frustrum of a large hollow cone, will be occupied by the engines which are to work the crane, together with a quantity of gearing.

The engines and gearing thus enclosed will derive their support not from beneath but from above, though they will be steadied a central pivot at base. The support from above is given by means of four cast-iron columns, slung from a revolving capital designated the "roller cap." As the radius girder sweeps round the circular area so the capital of the central group of columns revolves with it, carrying the engines and gear supported on a stage at the lower end of the four interior columns. The revolving capital travels on live rollers of cast iron 16 inches in diameter, interposed between the capital and the annular girder entablature which holds the summits of the eight columns.

Summarising the vertical dimensions of this part of the crane, we have first of all the eight columns rising to altitude of 43 feet, supporting an entablature four feet in depth, being the upper annular girder. On this are the live rollers, supporting cast-iron "cap," or capital, which adds 3ft. 6in. to the vertical height. On this again comes a centreing piece, 2 ft. deep, hollowed in its centre so as to cover what may be termed a knob of metal, 18in. high, in shape resembling half an egg standing on its base, and rising up from the roller cap. This arrangement constitutes what is termed "knuckle bearing." The extremity of the great horizontal girder being attached to the strong casting centreing piece which we have just described, and the same knuckle bearing arrangement existing at the other end, a proper amount of play is allowed, supposing there should be any deflection when lifting heavy weights. Proceeding to speak more particularly of the radius girder which connects the summits of the centre and outer groups columns, we must specify it as composed of two horizontal wrought-iron girders of the bore [box?] type, about 75 feet in length, with a depth increasing towards the centre, where it is 8 feet 6 inches, The chain carriage, supported on eight wheels, runs on rails attached to the upper flanges of the two girders, and is traversed from end to end by means of chains and gearing worked by the engines previously named. This carriage bears the lifting blocks, which are of large size, having cast-iron sheaves about four feet in diameter The outer extremity of the girder—or compound girder— on which this carriage runs, is supported by six cast-iron columns of somewhat similar design to the eight which are at the inner end. The six outer columns spring from an iron carriage running on eight wheels about five feet diameter. These wheels are arranged in four following pairs, and travel on rails of the regular railway gauge, namely 4ft 8½ in. The circle traversed by this carriage has a diameter of 136 feet measuring to the centre of the rails. The rails are ribs raised on plates. The wheels of the carriage are made to rotate by gearing set in motion from the engines by two vertical shafts and one cross shaft. That is to say, the shafting extends up the central group of columns, along the top girder, and down the outer group. The revolution of the wheels on the railway gives motion to the whole structure, the great top girder sweeping round over the entire space. The actual height to the top of the horizontal girder is feet inches. The extreme height, going to summit of the chain carriage, is about 70 feet.

The engines in the central group of columns will consist of two steam cylinders, 16 inches in diameter, and with a 16-inch stroke. The steam will be supplied from the forge boilers, which are adjacent. When a heavy weight has to be lifted these engines will work the spur gearing acting on two chain barrels each six feet in diameter.

There will be lighter gear for inferior loads to 20 tons, for which there will be independent chains working on two smaller barrels. The links of the great lifting chain will be composed of iron 2¼ inches in diameter. The crane is estimated to lift 200 tons; but the breaking strain of the girders will be six times that. The full lift of 200 tons will be worked at the ascending rate of half a yard per minute. The speed of the 100-ton lift is a yard per minute, and that of the 50-ton lift two yards per minute. The light lift of 20 tons will be worked at the rate of 14½ feet per minute. It will thus be seen that the action of this new description of crane requires a circular railway more than 400 feet in circumference, being the same gauge as that which characterises railways in general. The motive power will be under the control of one man, standing on the stage inside the central group of columns. By simply laying his hand on one or the other of set of levers this man will be able to direct all the movements of the great machine, lifting, if necessary, a couple of 81-ton guns at one time, with the addition of a 38-ton gun to make up a full load. This enormous weight will not only be lifted, but moved about with perfect facility over the space of nearly a quarter of an acre.

The crane was scrapped in 1937 and a new all-electric version installed

More info here on this video presentation (Start time copy 19:17) https://youtu.be/GW2aToc3xaU?t=1182

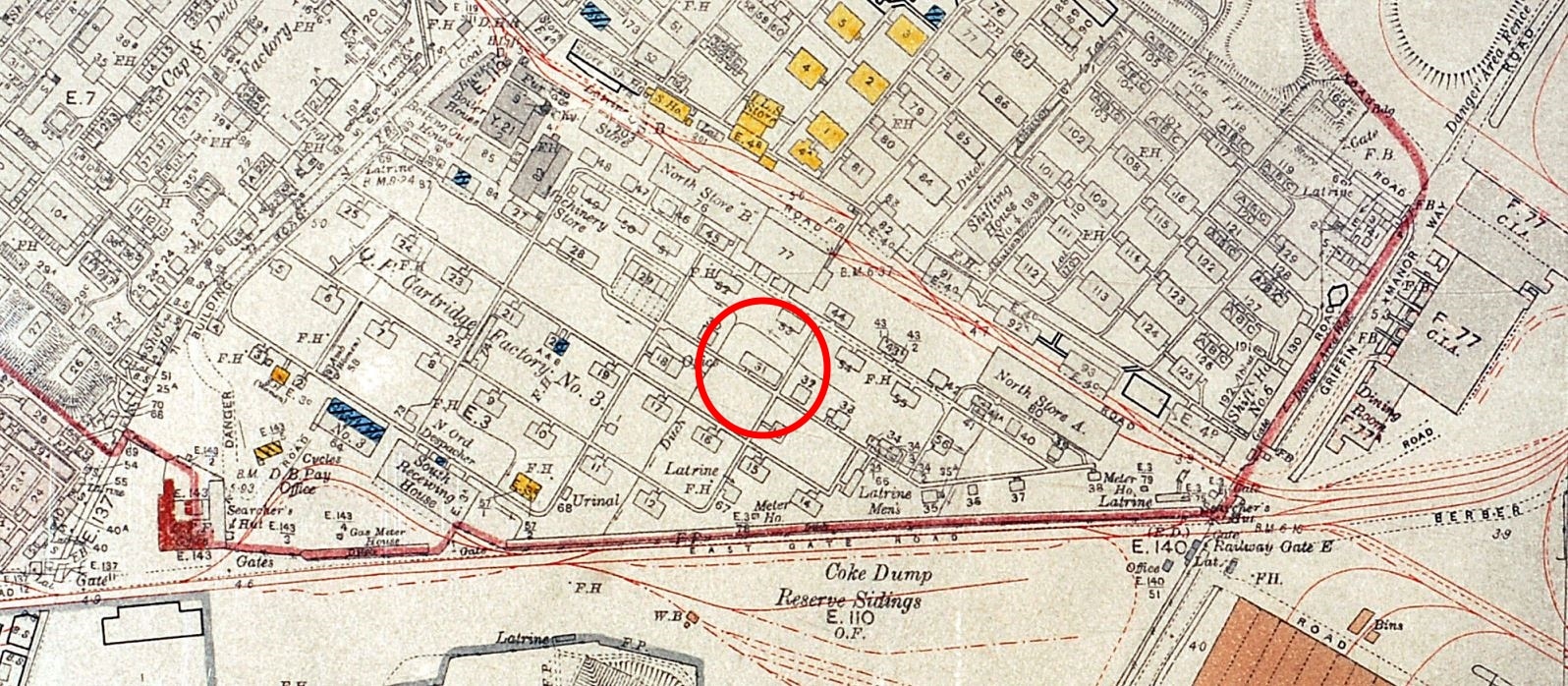

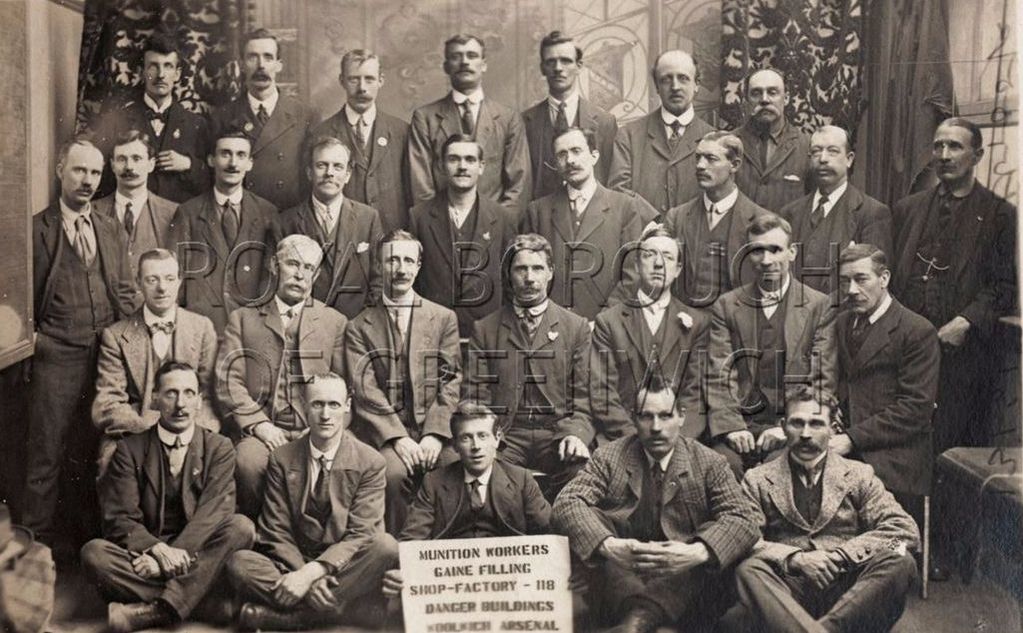

Area E - Danger Buildings

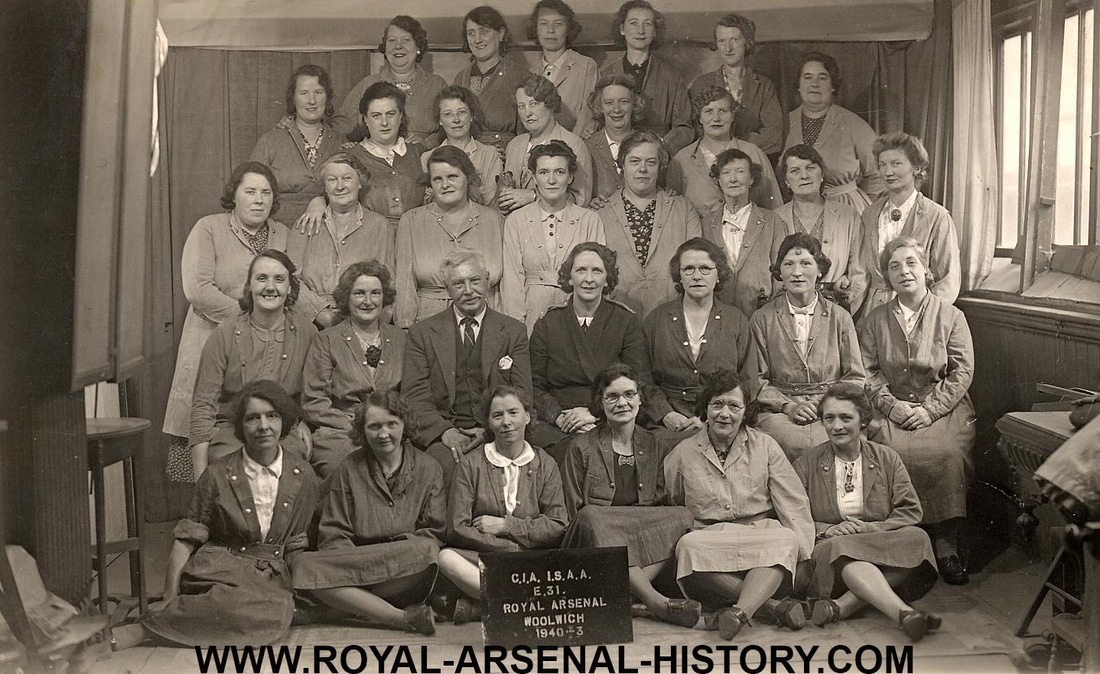

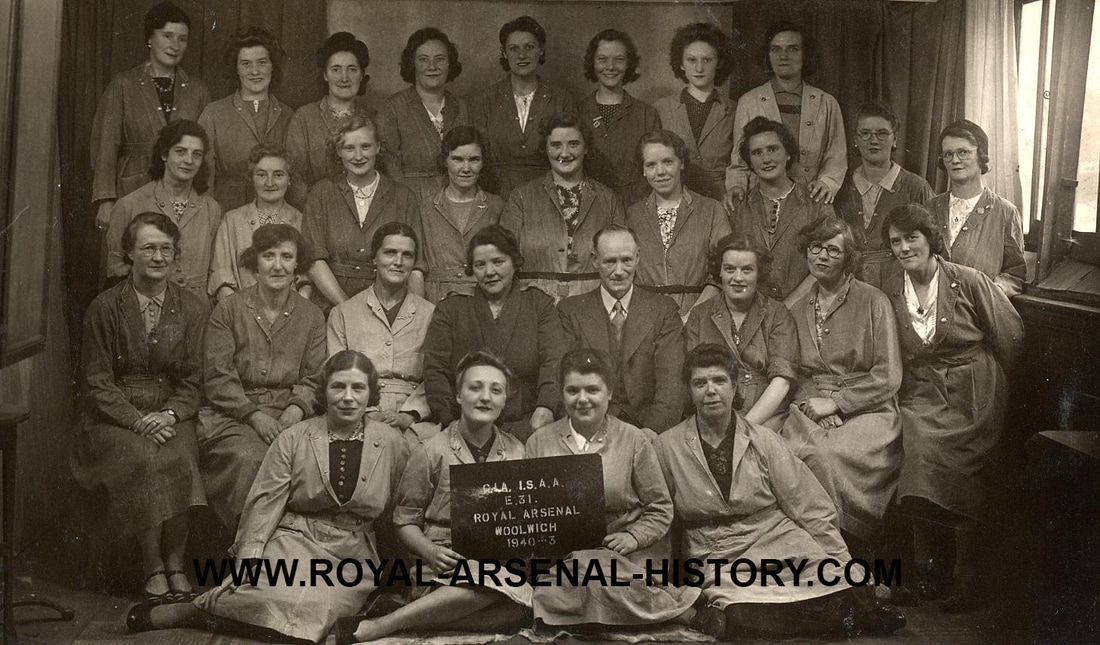

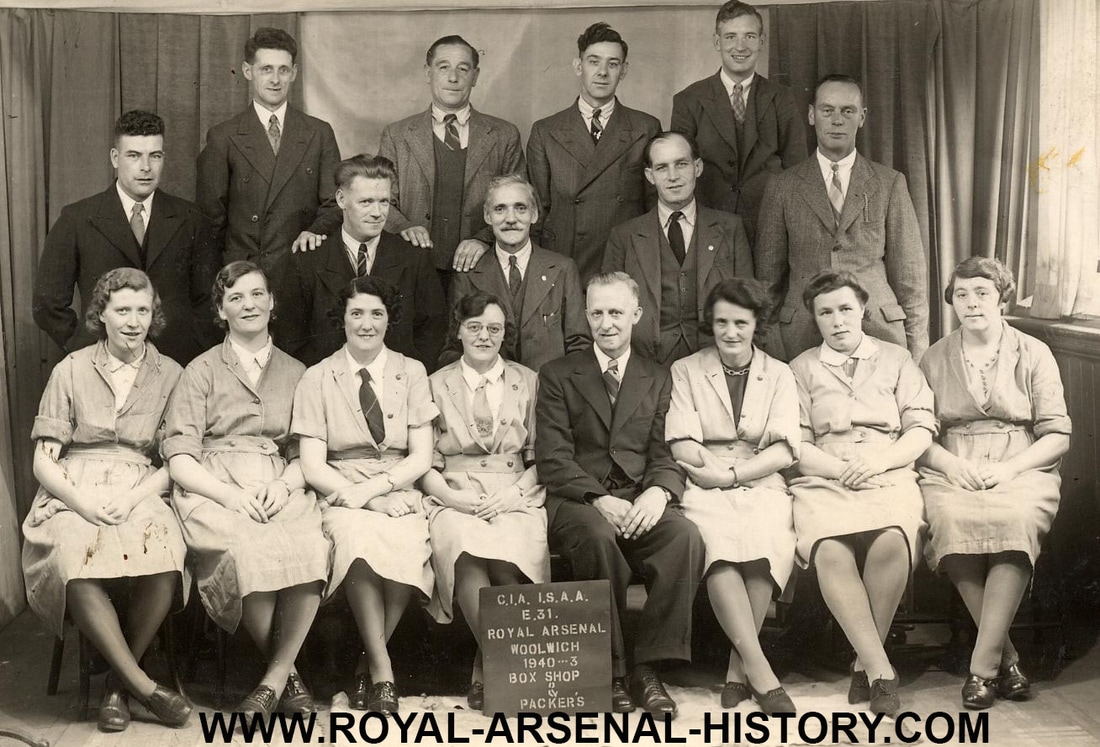

E31 Examination Store - Examination Shop Inspection | S.A.A Small ARMS Ammunition Factories | C I A Chief Inspector Of Armaments Inspection Dept

Danger Building Women Workers

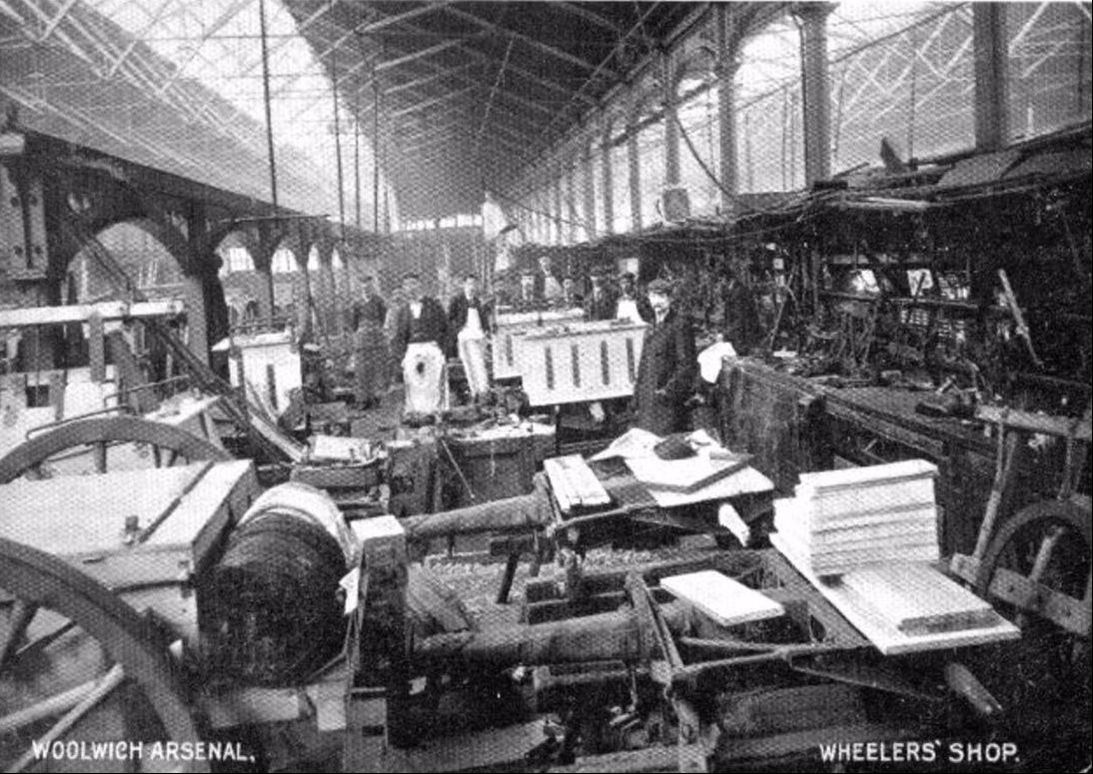

E55 Carpenters & Wheelers shop

Area F

Royal Arsenal East /Plumstead Marshes / Thamesmead

F6a No.1 Army Magazine

F72 - Wood Machine Shop Wheelwrights

F111 Examination Shop Inspection | S A A Small ARMS Ammunition Factories | C I A Chief Inspector Of Armaments Inspection Dept

Work in progress (August 2023)