Royal Arsenal Departments

PD Proof Department

RCD Royal Carriage Department

RGF Royal Gun Factory

RL Royal Laboratory

SD Store Keepers Department

|

Acronym |

Description |

|

A

D M T |

Army

department of mechanised transport |

|

A

O S |

Army

Ordnance Stores ( R O A C ) |

|

B

W D |

Building

Works Dept |

|

C

D |

Catering

Dept |

|

C

I A |

Chief

Inspector Of Armaments Inspection Dept |

|

C

S O F |

Chief

Superintendent of Ordnance Factories |

|

M

E D |

Mechinical Engineering Dept |

|

I

O |

Indian

Office |

|

I

N O |

Inspector

Of Naval Ordnance |

|

M

B |

Mechanisation

Board |

|

M

D |

Medical

Dept |

|

N

I D |

Naval

Inspection Dept |

|

O

C |

Ordnance

Select Committee |

|

O

F S |

Ordnance

Factory Stores |

|

P

O |

Pay

Office |

|

R

A F |

Royal

Ammunition Factory |

|

R

G C F |

Royal

Gun & Carriage Factory |

|

R

C D |

Royal

Carriage Dept |

|

R

G F |

Royal

Gun Factories |

|

R

A R D E |

Royal

Arsenal Research & Development Establishment |

|

R

E M E |

Royal

Electrical & Mechanical Engineers |

|

R

D |

Research

Department (R I ) |

|

R

N A D |

Royal

Naval Armament Dept |

|

S

A A F |

Small

ARMS Ammunition Factories |

|

S

A D |

Stores

Audit Department |

|

U

K A E A |

United

Kingdom Atomic Energy Authorities |

|

W

D C |

War

Department Chemist |

|

W

D C |

War

Department Constabulary |

|

W

O A B |

War

Office Audit Board |

|

W

D F B |

War

Department Fire Brigade |

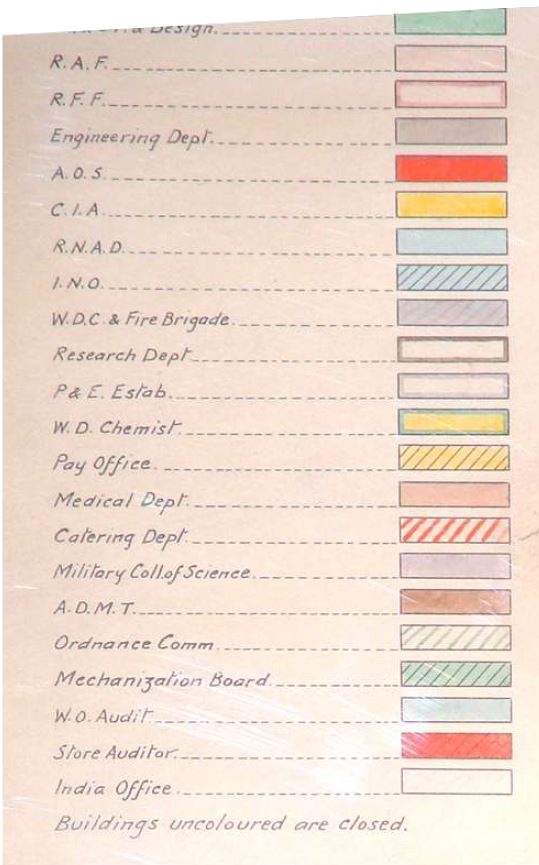

1931 Secret MAP

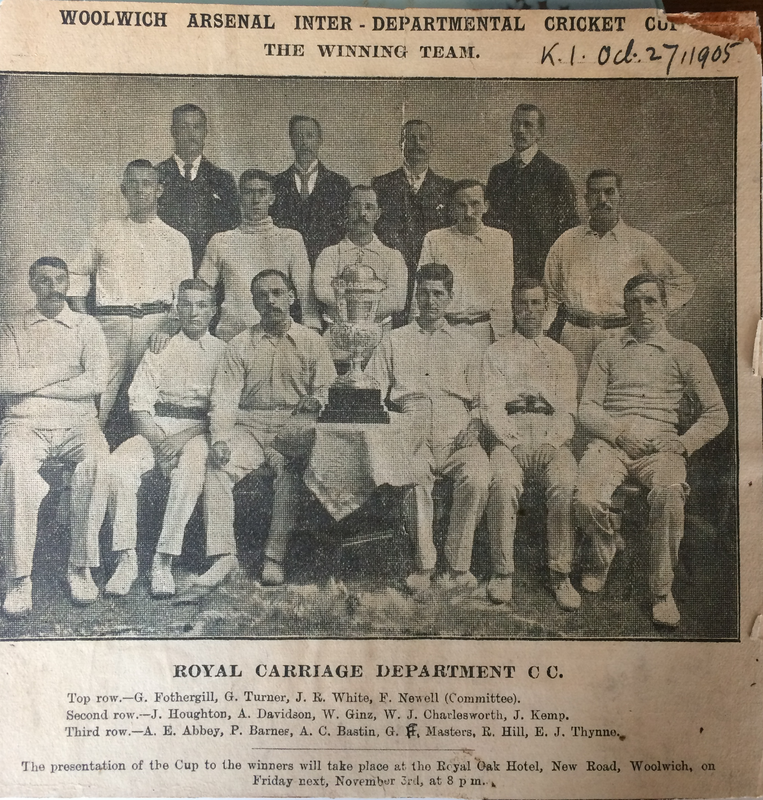

Royal Carriage Department

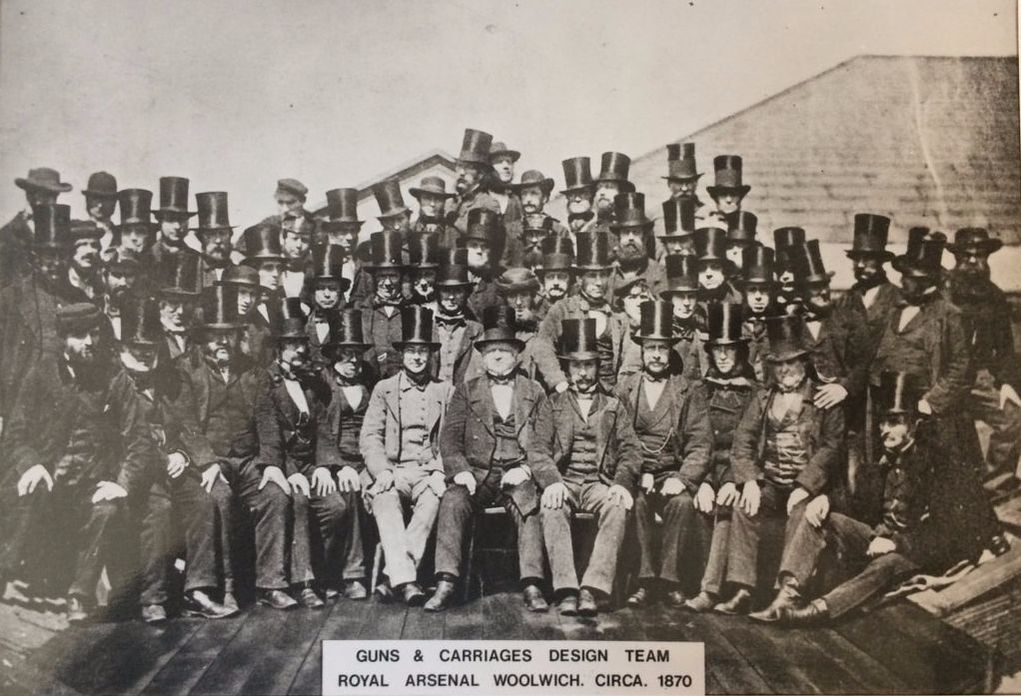

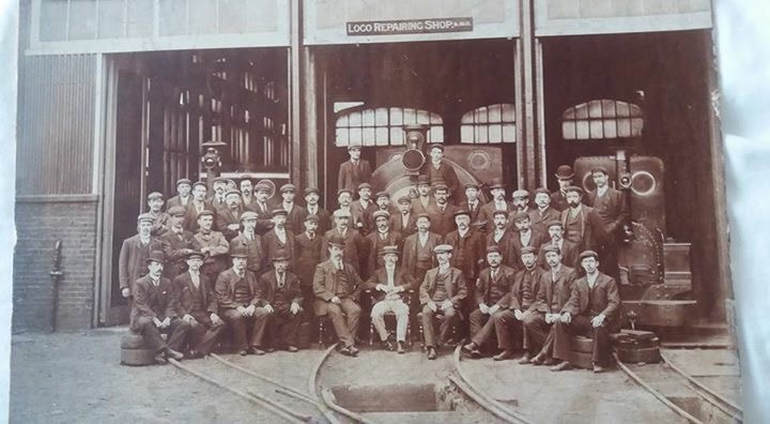

It measures approx. 54 inches in width and 10 in height and has been scanned and stitched to upload this photo.

The photo was taken outside the Royal Arsenal's Central Offices.

They all have just played their part in winning the First World War. To do that they would have worked 12 to 14 hour shifts every day except 6 to 7 hours on Saturday and a day off on Sunday. They would have had no holidays since 1914, no wonder they thought it worth having a record of themselves.

The RCD employed many thousands at this time. Unlike the management, they didn't get photographed...

Royal Guns and Cartfidge Factory (RGCF)

CIA - Chief Inspector Of Armaments

Mechanical / Engineering Department

RARDE "ARD High Explosoves" Department

:-

| 1. Col. Mozozen | Polish Officer | ||

| 2. T.E Wallace | E.A.II | ||

| 3. R. F. J. Freeman | E.O. | “Professor” | |

| 4. Dr L. R. Outridge | S.O | ||

| 5. J. V. Westwood | E.O. | ||

| 6. Capt. Hackel | Polish Officer | ||

| 7. P. Cliffe | E.O. | “Percy” | |

| 8. V. Jamieson | A.I. | “Jimmy” | |

| 9. C. B. Roberts | E.O. | “Carl Brian” | |

| 10. D. McKenzie | S.S.O | “Mac” | |

| 11. C. J. A. Cooper | S.O. | ||

| 12. R. A. W. Walker | A.II | “Bill” | |

| 13. Dr J. G. Bennet | E.O. | ||

| 14. E. V. Saunderson | S.O. | “Sandy” | |

| 15. Dr W. E. Soper | S.O. | ||

| 16. W. E. Slater | S.S.O | “Trauzyl” | |

| 17. R. G. Early | P.S.O | “Mum” | (Head of section) |

| 18. W. L. Long | S.S.O | “Dad” | |

| 19. W. A. Bailey | S.S.O | “Uncle B” | |

| 20. Dr J. W. Rowe | S.E.O | “Doc” | |

| 21. H. B. Young | A.II | “H. B.” | |

| 22. P. E. Hall | A.III | “Sam” | |

| 23. R. M. Laidler | A.II | “Ronny Mac” | |

| 24. J Williamson | E.O. | “Jock” (By himself) | |

| 25. R. W. Bolland | E.O. | ||

| 26. D.E. Jarrett | E.O. | ||

| 27. J. S. Beard | E.O. | “Bluebeard” | |

| 28. H. J. Lacey | E.AIII | “Hugo” | |

| Other members | |||

| Miss M. Arnold | A.I. | “Matthew” | |

| K. Reed | E.O. | ||

| E. V. Wobschall | E.A.III | ||

| J. A. Jackson | L.A. | ||

| Mrs M. Allwright | Clerk | ||

| Miss S. Woolgar | Clerk | ||

| Miss P. Prime | Clerk | ||

| S. Brown | Clerk | ||

Quality Assurance Directorate Ordnance QAD(Ord)

Quality Assurance Directorate Weapons (QADW)

Quality Assurance Directorate Fighting Vehicles and Engineer Equipment merge (QADFVE)

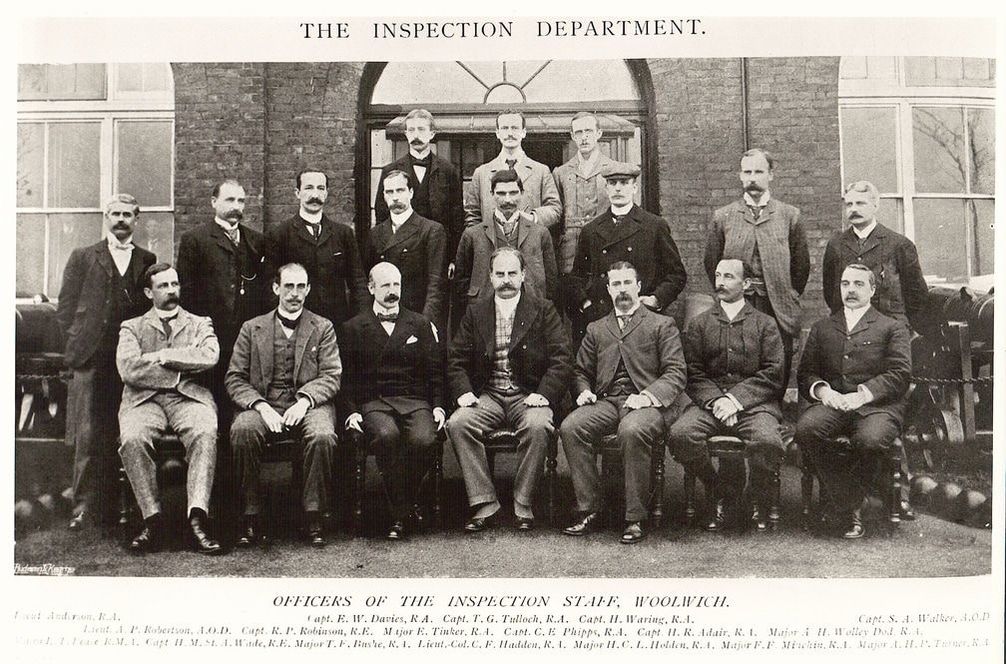

The inspection of Government stores, particularly armaments, was first mentioned in a Warrant dated 21 December 1456, appointing a Master of Ordnance to discharge this responsibility as well as the provision of warlike materiel.

In 1543 the post of 'Surveyor' was created in the Office of Ordnance and by 1683 the examination of ammunitions rested with the Surveyor-General of Ordnance, Over succeeding years abuse gradually crept in to such an extent that the quality of stores delivered to the Armed Forces became extremely poor. Thus, in 1783 the proof of guns and ammunition was transferred from the Surveyor- General to the Inspector of Artillery at the Royal Brass Foundry in Woolwich Arsenal.

Woolwich was thereafter to remain the centre of inspection until the outbreak of World War II.

Towards the end of the 19th century an Inspector of warlike stores was appointed.

At that time the Factories at Woolwich were responsible not only for the inspection of their own products but also those from the trade. To effect this inspection, military officers, usually known as Captain Inspectors were included on the staff of each Factory.

In 1886 the Government set up a Committee under the Earl of Morley to enquire into the organisation and administration of the manufacturing departments of the Army and to submit recommendations.

The main innovation resulting from the subsequent Morley Report was the inauguration of an independent authority to to the Army resulted in the appointment of an Assistant Director of Artillery, Woolwich, to control these activities. Shortly afterwards he was redesignated 'Chief Inspector, Woolwich'. This may be said to be the true origin of the QADs as

we know them today (printed 1980).

In 1904, following the Boer War, the Esher Committee recommended further radical changes in the structure of the War Office.

The MGO was made responsible for the design, trial, manufacture and inspection of all armaments. These duties were partly delegated to the Director of Artillery, who controlled the Ordnance Factories where design and production took place, giving him full charge over the various Inspection Departments.

At the same time the QMG assumed responsibility for the storage and issue of clothing and general stores. During World War 1 the Ministry of Munitions was formed to take over the

expanding business of research, design, testing and production of warlike stores.

This Ministry was disbanded in 1920 when the function reverted to the War Office

under the direction of the MGO.

One of the lasting effects of World War 1 derived from the advent of mechanisation. Not only did mechanical transport find universal acceptance but the tank had al so arrived. The demand for AFVs and transport vehicles grew withastonishing rapidity.

By 1924 the Director of Artillery's function was divided and there emerged a Director of Artillery 1 - to control artillery development and a Director of Artillery 2 - to deal with mechanisation and small arms.

In 1927 the Director of Artillery 2 was restyled Director of Mechanisation, when Director

of Artillery 1 assumed additional responsibility for the development of engineering and bridging stores.

Some little while later, small arms passed to the Director of Artillery and in exchange, engineering and bridging equipment came under the sponsorship of the Director of Mechanisation.

By 1930 MG had 4 Directors: Director of Artillery, Director of Mechanisation, Director of Ordnance Service and Director of Ordnance Factories. Between them they covered virtually every aspect of modern weapon procurement including research, design, development, testing, production, inspection, maintenance, custody and issue.

On 14 September 1936 the office of Master-General of the Ordnance was suspended.

It was not reinstated until 1960 when the Ministry of Supply was abolished.In his new post, the Director of Mechanisation concluded that the inspection techniques and procedures for weapons were not always suitable or indeed applicable to the mechanical and automotive engineering processes involved with vehicles. Thus, in 1937, a Deputy Chief Inspector of Armaments (Tanks) was appointed who, although answerable to CIA, was technically responsible

to the Director of Mechanisation. With the formation of the Ministry of Supply in August 1939, DCIA (Tanks) was renamed Chief Inspector of Mechanisation (latterly DQA(FVE)) and the Inspectorate was removed from the control of CIA and made directly responsible to the

Director General of Tanks & Transport in the new Ministry. It is of interest to note that there were 7 separate stores Inspectorates in the Ministry of Supply. These dealt respectively with Armaments, Aircraft, Engineering & Telecommunication Equipment, Vehicles, Chemicals, General Stores and Clothing.

The peak wartime complements of all grades in these Inspectorates totaled 80,000,

although by 1948 it had dwindled to less that 10,000. With the outbreak of World War II the various Inspectorate Headquarters were dispersed from the Royal Arsenal, Woolwich and mostly scattered around schools, offices and large houses near the Kent county border.

The Inspectorate of Armaments retained its workshop and test facilities in Woolwich Arsenal, but

moved its Headquarter staff into Red Barracks, Woolwich CIM's department

occupied large houses in the Bickley and Chislehurst area and by 1942 had al so acquired a site at Farnborough, Hants, to accommodate its expanding laboratories and Test House. In 1952, as the Inspectorate of Fighting Vehicles, the HQ staff moved into more suitable accommodation at Kidbrooke.

Here are acronyms for some of QAD departments and locations.

QAD(W), QAD(ORD), DGDQA, DGDQA QATS, DERA, QAD(W) Apprentice training shop, Metrology Lab,C58,Garland Road, DGDQA Apprentice Training Centre 10A, SSU, Site Services, NDT, Lubricants Lab, DRA DERA. Bldg 7 and C1 (Building 19).

IFVME (Inspectorate of Fighting Vehicles and Mechanical Equipment).It subsequently changed name's to MQAD (Materials Qaulity Assurance Directorate) .Then QAD(Mats)and then to QAD(TS) and finally in 1993 to DRA Fuels and Lubricant's .Building 6 (The Mechanical Testing of Lubricant's Laboratory) left the Arsenal in late March 1994 to it's new home in Chobham Surrey and then to Pystock Hants

DSTL History going back to Royal Arsenal Woolwich